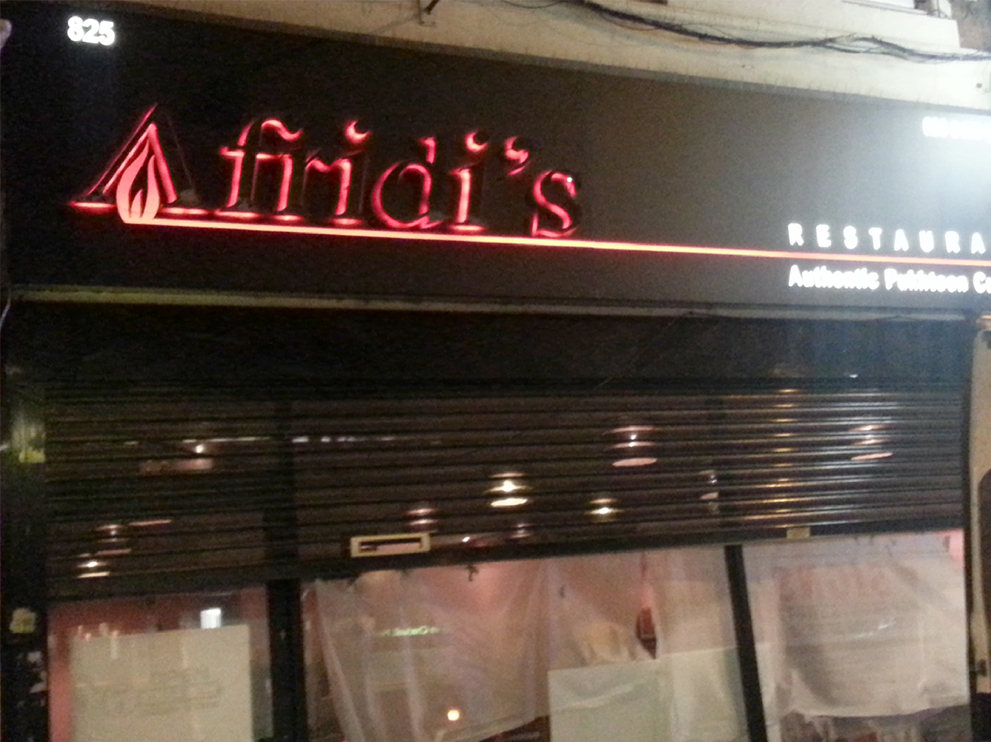

Illuminated Tray sign with stainless steel letters

Illuminated Tray sign with stainless steel letters offer a sleek and modern aesthetic, combining durability with eye-catching visibility. The stainless steel letters, precision-crafted for longevity and sophistication, create a bold contrast against the backdrop of the sign. Whether installed individually or as part of a larger sign, these letters provide a high-end, professional appearance. The incorporation of illumination enhances the visual impact, making the signage stand out day and night. The sleek, reflective surface of the stainless steel letters further amplifies the effect of the lighting, resulting in a dynamic and attention-grabbing display that not only communicates your message effectively but also adds a touch of sophistication to your brand presentation.

The manufacturing process of stainless steel 3D letters involves precision and expertise to create durable, high-quality signage. Here’s a step-by-step overview of the typical manufacturing process:

Design and Specification: The process begins with the creation of a detailed design, specifying the dimensions, font, and style of the stainless steel 3D letters. Considerations for illumination, if required, are also included in the design phase.

Material Selection: Stainless steel sheets are chosen for their durability, corrosion resistance, and aesthetic appeal. The thickness of the steel is determined based on the size and structural requirements of the letters.

Cutting and Shaping: Using advanced cutting techniques such as laser cutting or CNC cutting Machine, the stainless steel sheets are precisely cut into the desired shapes and dimensions. This includes cutting out the letters and any additional design elements.

Bending and Forming: The cut stainless steel pieces are then bent and formed to create the three-dimensional structure of each letter. This step requires careful craftsmanship to achieve accurate angles and curves.

Welding and Assembly: The individual components of each letter are welded together, ensuring a strong and seamless bond. This step is crucial for the structural integrity of the stainless steel 3D letters.

Surface Finish: The stainless steel letters may undergo various surface treatments to achieve the desired finish. Common finishes include polishing for a reflective surface, brushing for a matte finish, or coating for added protection against corrosion.

Mounting Options: Depending on the design and application, mounting brackets or other hardware may be attached to the back of each letter during the assembly process. This facilitates easy installation on walls or other surfaces.

Quality Inspection: Each stainless steel 3D letter undergoes a thorough quality inspection to ensure that it meets the design specifications, has a consistent finish, and is free from any defects. Illumination Installation: If the design includes illumination, LED modules or other lighting components are installed within the stainless steel letters. This may involve creating openings or channels to accommodate the lighting elements.

Final Inspection and Installation: A thorough final inspection is conducted to ensure that each stainless steel 3D letter meets the required quality standards before it is installed on the sign or wall.

This process ensures that stainless steel 3D letters not only convey a sense of quality and professionalism but also withstand the test of time and environmental conditions.

Don’t hesitate to contact us today to schedule a consultation or simply fill out the form provided. Select the options that most closely align with what you’re looking for, and our experienced team will promptly furnish you with pricing information and expert suggestions customized to your particular preferences. This process will provide you with a clear grasp of the expenses involved, enabling you to plan your budget with confidence.